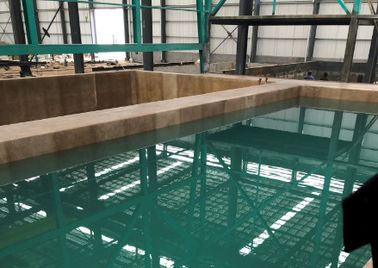

ISO Certificate Hot Dip Galvanizing Equipment With CNC Control System

This system adopts the vertical arm hand type lifting device, compared with the traditional vehicle or electric hoist, with accurate positioning, no shake, can achieve a stable sling hold up and down, to avoid the slings and workpiece fall into the acid pool, and my company independent research and development of the hoisting device, with the PLC automatic control program, can be intelligent the lifting task is adjusted by the process of pickling time recording processing groove, adjust the hand task, reduce the load time, the precise control of the pickling time and automatically enter and put forward into the next process of pickling tank tank.

Specifications

1. Compective price

2. Energy saving

3. good quality

4. Clean and economical

5. leading manufacturer

This system allow manual control interface in the pickling effect unqualified when artificial intervention, and real-time data recording, the formation of large data, the future through big data analysis, according to the acid concentration and temperature, the shape parameters, automatic formation of reasonable pickling process.

1. track is shared with an enclosed single beam, with a distance of about 32 meters.

2. configuration holder 2 sets, single set of hand load 10T, running speed of 10-20m/min;

3. supporting hand is equipped with vehicle control PLC, frequency converter, wireless communication module, code reader, track locator, RFID recognition system and so on to control the original device, and the protection level of electric control box is IP65.

4. system uses the sliding contact line, the collector supply of the car power supply; all units and the main control system adopts industrial control between wireless Ethernet, implementation of vehicle PLC and ground PLC master data exchange.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!