8-XLY Fume free Acid Pickling Line Φ0.5mm-Φ12.5mm acid pickling with high efficient

Acid Pickling Production Line

1) Coil lifter

2) Decoile

3) Guide and shovel device

4) Pinch roll and 3-roll straightener (steel frame)

5) Hydraulic shearing machine

6) Centering welding platform

7) Pinch roll and derusting device

8) Loop bridge (supply by user)

9) Guide & pinch roll and leveler

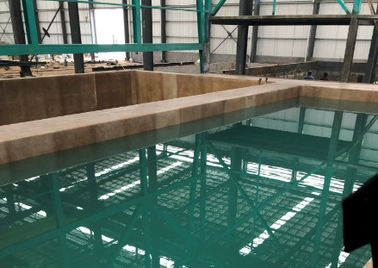

10) Pickling groove

11) Extrude acid roll

12) Cleaning groove (supply by user)

13) Scrub machine

14) Passivation groove

15) Extrude to dry roll (steel frame)

16) Hydraulic shearing machine

17) Vertical roll centering device

18) 3-roll expansion machine & inunction device

19) Recoiler

20) Unload car

.

Process flow of continuous pickling line

Loading manually →Coil loading car→No.1 payoff reel → No.1 payoff scraper→No.2 payoff reel →No.2 payoff scraper →No.1 five-roll straightening leveler →No.2 five-roll straightening leveler →Deflector roll→Double-layer shear →Converge pinch roll →Welding machine →No.1 bridle roll →No.1 horizontal loop →No.1 CPC →No.2 bridle roll →descaler →No.3 bridle roll →No.2 double roll CPC →Pickling →Water washing →Drying →Loop →No.4 bridle roll →Pinch CPC unit →Scrap coiling →Three-roll tension roller →Exit shear →Oiling machine →Exit deflcting pressing roll→ Tension reel →Coil unloading car →Coi receiving table

Pickling Line

We offer Push-Pull, semi-continuous and continuous pickling lines.

Push-Pull lines process one coil at a time, thus removing the need for joining strips. This allows tremendous flexibility of operation and ensures ease of operation and maintenance. As there is no need for accumulators in such lines, these lines have very low cost of investment and are very much cost-effective for medium volume of production.

Additional Features:

Additional features like Edge-Trimming, Skin-Passing, Coating, Cut-To-Length etc. can be incorporated as per the requirements of the customer.

Key Specification

- Solution could be recycled, no pollution discharged

- Occupied area is less than traditional pickling

- Acid: dilute phosphorous / hydrochloric acid

- Wire diameter: Φ0.5mm-Φ12.5mm

- Wire number: 8-40

- Safe, high efficient

- Desinged according to customer's requirement

-

This system allow manual control interface in the pickling effect unqualified when artificial intervention, and real-time data recording, the formation of large data, the future through big data analysis, according to the acid concentration and temperature, the shape parameters, automatic formation of reasonable pickling process.

1. track is shared with an enclosed single beam, with a distance of about 32 meters.

2. configuration holder 2 sets, single set of hand load 10T, running speed of 10-20m/min;

3. supporting hand is equipped with vehicle control PLC, frequency converter, wireless communication module, code reader, track locator, RFID recognition system and so on to control the original device, and the protection level of electric control box is IP65.

4. system uses the sliding contact line, the collector supply of the car power supply; all units and the main control system adopts industrial control between wireless Ethernet, implementation of vehicle PLC and ground PLC master data exchange.

Our Services

We will offer basic layout and electrical system diagram of production line within 30 days after signing the contact.

We will supply all information when delivery ,including line electrical drawing,original manual of equipment and instrument table,equipment conformity certificates,list of spare parts,equipement maintanance procedures,drawing and suppliers of quick-wear pats.

We will send engineer and high level technician when installing the production line.

We will test the whole line for one month and train the operater.

We will send engineers to service machinery overseas if necessary.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!